Heterogeneous Catalysis Unit

THE UNIT IN 2013

The Unit provides support to the researchers of the Institute working in heterogeneous catalysis (gas phase reactions catalysed by solids). Other research lines involving solids characterization, from a chemical and a physical point of view and on-line analysis of gases can also benefit from the Unit. State-of-the-art techniques for the catalysts characterization and testing are available to carry out both conventional experiments and advanced applications that are developed in collaboration with the research groups or other research units.

Several experiments requiring the application of a new technique were run during 2013:

- The microporosity (pores <2nm) of materials to be constituent of membranes, was analyzed carrying out isotherms starting at a pressure as low as ca. 3E-7 bar.

- Monitoring by MS of photocatalytic reduction of CO2 with H2 in a normal reactor and in an in situ FTIR set-up.

- Analysis by MS in a capillary reactor in the context of in situ XAFS (X-ray absorption fine structure) measurements carried out at ALBA synchrotron.

- Pulses of 0.34 cc of N2O were made to determine the metal surface area of copper-containingcatalysts. N2O at the reactor outlet was retained by liquid Ar (87 K).

MOST IMPORTANT EQUIPMENT

- AUTOSORB iQ®(QUANTACHROME).

- micro-Ultrapycnometer 1200e®(QUANTACHROME).

- TPDRO 1100®(Thermofisher).

- Microactivity Reference®(PID Eng&Tech).

- OMNISTAR® (Pfeiffer) and 6890N (Agilent). Two MS and a GC for the on-line analysis of gases.

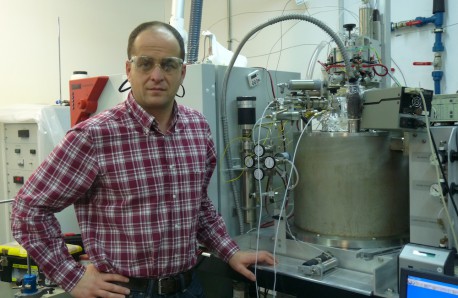

- TAP-2 reactor (Mithra Technologies®).

- Nano-ZS (Malvern®).